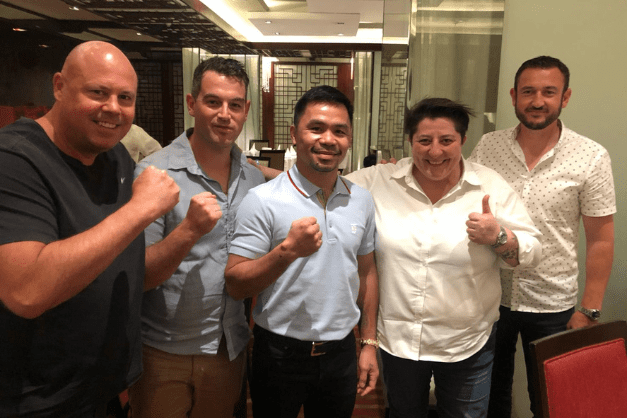

Maryann Farrugia is the managing director at Offshore Business Processing, a Manila-based business process outsourcing (BPO) firm. The company works with freight forwarders around the world to manage their back-office tasks, including job filings, ISF, transport coordination, and more.

In this op-ed, Farrugia shares how she’s seen freight forwarders optimize efficiency and increase margins in a challenging shipping market. She also discusses how freight forwarders can leverage operational improvements like offshoring and tech adoption without overhauling their process.

Hear more advice from Farrugia in our recent webinar, The Key to Maintaining Operational Efficiency From Bookings to Warehouse.

In the past few years, we’ve seen drastic shifts in the freight forwarding industry. During the pandemic, shipping margins were higher than ever. At that time, many forwarders started spending much more on hiring and paying their staff to keep up with the demand.

Now, margins are dropping, and shipping lines are returning to how they were before COVID. In the current landscape, many forwarders can’t afford to keep operating as they did in the supply chain surge.

How forwarders are competing in today’s industry

At OBP, we’re seeing how this economic shift affects freight forwarders. Before COVID, forwarders typically come to us to reduce labor costs. They’re seeking us out because they simply can’t find people in their market.

With the global labor shortage, logistics providers find that supplementing their existing team isn’t just beneficial to their business– it’s necessary. Increasing headcount isn’t an option because those people aren’t available in the market, and the talent there is costly. That’s where many forwarders have been seeking solutions like offshoring and automation.

For those who are new to offshoring, I’ll give a quick explanation of what it is and how it works. Offshoring is the practice of outsourcing some of your business tasks to a third-party partner in another country to improve efficiency and decrease labor costs. When you offshore your operations as a freight forwarder, you’ll hand off manual tasks like data entry, job filings, or customs clearance procedures.

As shipping rates decline, we see many freight forwarders using our offshoring services to increase their margins.

I’ll share an example I talked about in a webinar with NCBFAA last month:

We worked with a top 10 global freight forwarding company that wanted us to manage their customs data entry. First, we set them up with 23 people in the Philippines to swap out their team in Australia, which saved them $50,000 per head. But they didn’t want to stop there– they asked us to come in, look at their processes, and implement a workflow.

Over the next 12 months, the company grew 25%, and thanks to the changes we implemented to re-engineer their processes, we didn’t have to add one extra person to handle that growth. So, in addition to their savings of over $1 million from offshoring, they didn’t have to increase staffing costs at all to keep up with the business expansion. Ultimately, we saved them over $16 million in the eight years we worked together through offshoring and workflows.

Making minor improvements toward efficient operations

When it comes down to it, growing your profits comes from increasing your margins. If you can minimize the cost per job, that can have a massive impact on your bottom line. Ideally, you want to do thousands of jobs for as little money as possible because that’s how you make money in freight forwarding.

At the same time, freight forwarders must understand this doesn’t have to be a complete overhaul. When you partner with companies like OBP and Logixboard, you don’t need to build an entire infrastructure before you can see a return.

Looking at how the multinationals operate, they’re taking on expenses like rent, talent acquisition, training, software developers, and IT. There are so many hidden costs in offshoring and developing in-house technology, but when you work with a provider, you don’t have to worry about that. With these solutions, you have the ability to compete against multinationals without spending millions.

The new direction of freight forwarding

As we see how quickly the industry changes, many freight forwarders are scared to take risks. But in this new landscape, I’m not sure how you will survive if you’re unwilling to adopt solutions like offshoring and technology.

I always tell my customers– as the supply chain moves back to normality, the digital shift that occurred isn’t going away. COVID accelerated tech adoption through remote work and the need for paperless operations, and it’s continuing to move forward.

At OBP, we commit to our customers to help them make more money. That’s why we’ve started partnering with logistics tech providers like Logixboard and Shipamax. We’re always looking for ways to make our forwarders more efficient, even if that means losing a few agents. We know this technology is coming, and as it becomes more pervasive across the industry, we want to be on the front foot.

Got any thoughts or opinions you’d like to discuss? Connect with Maryann on LinkedIn to continue the conversation.